| |

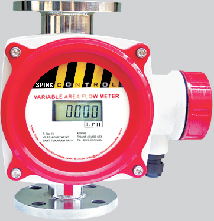

DIGITAL METAL TUBE ROTAMETER

|

|

It operates on the principal of variable area; the fluid in the metal tube raised a float in the taper tube increasing the area of passage of fluid. The float moves up in proportion to the rate of flow of fluid and get stabilized, when the weight of the float is balanced by the upward hydraulic force. By a magnetic coupling the inner float moment through a series of linkages and counter weight. The tube and the float combination determine the Flowrate. Digital Meter : The inner float magnetic field is detected by the high sensitive magnetic field detection sensor, enable us to show the digital readout As such this flowmeter does not require any electrical connection, since it operates on battery. It has an inbuilt two wire transmitter provide 24 VDC and take 4-20 mA Signal.

.png)

|

METAL TUBE ROTAMETER

|

|

Metal Tube Rotameter is a Variable Area Flow Meter. It consists of a tapered tube, typically made of steel with a 'float', made of SS or PTFE. The differential pressure across the annulus area is constant. The float moves through the tapered tube up and down with respect to fluid flow. The vertical position of the float as indicated by scale is the measure of the instantaneous flow rate.

.png)

|

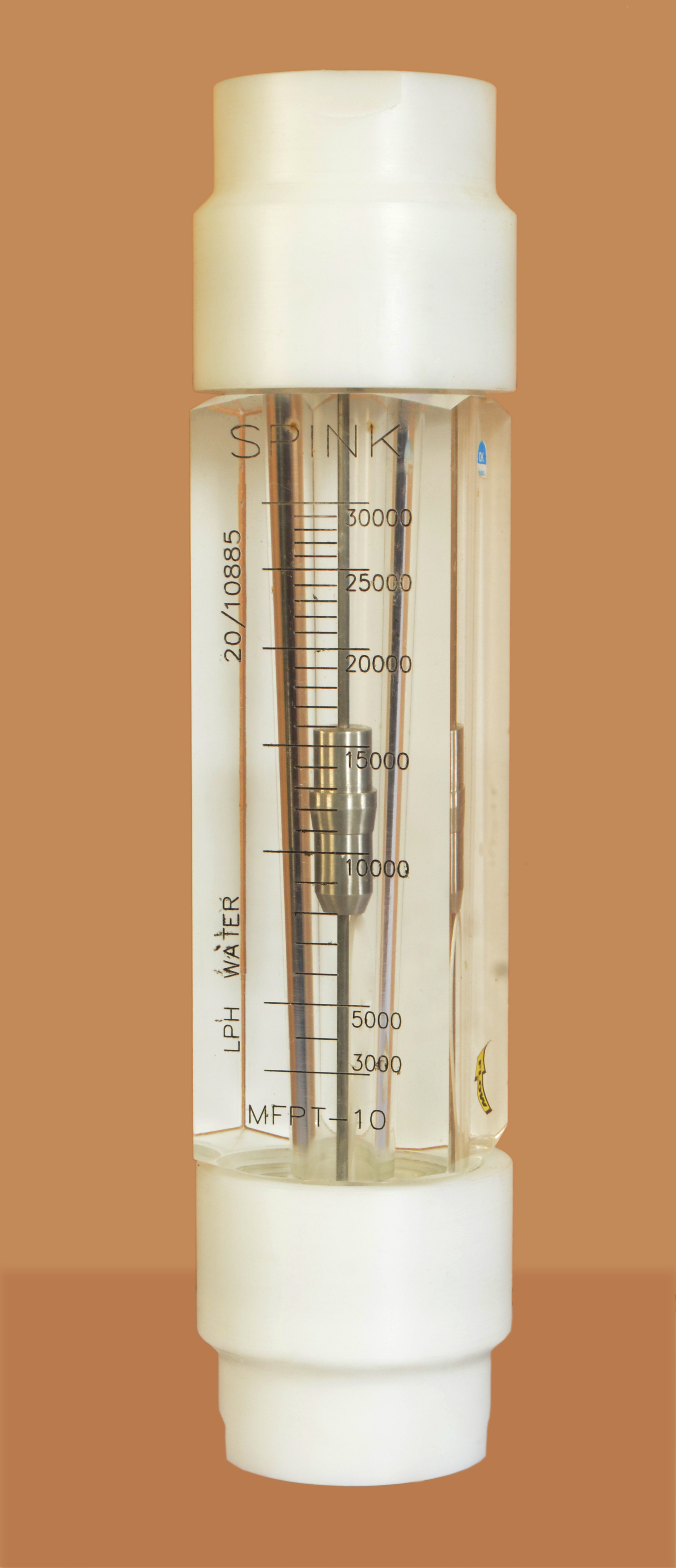

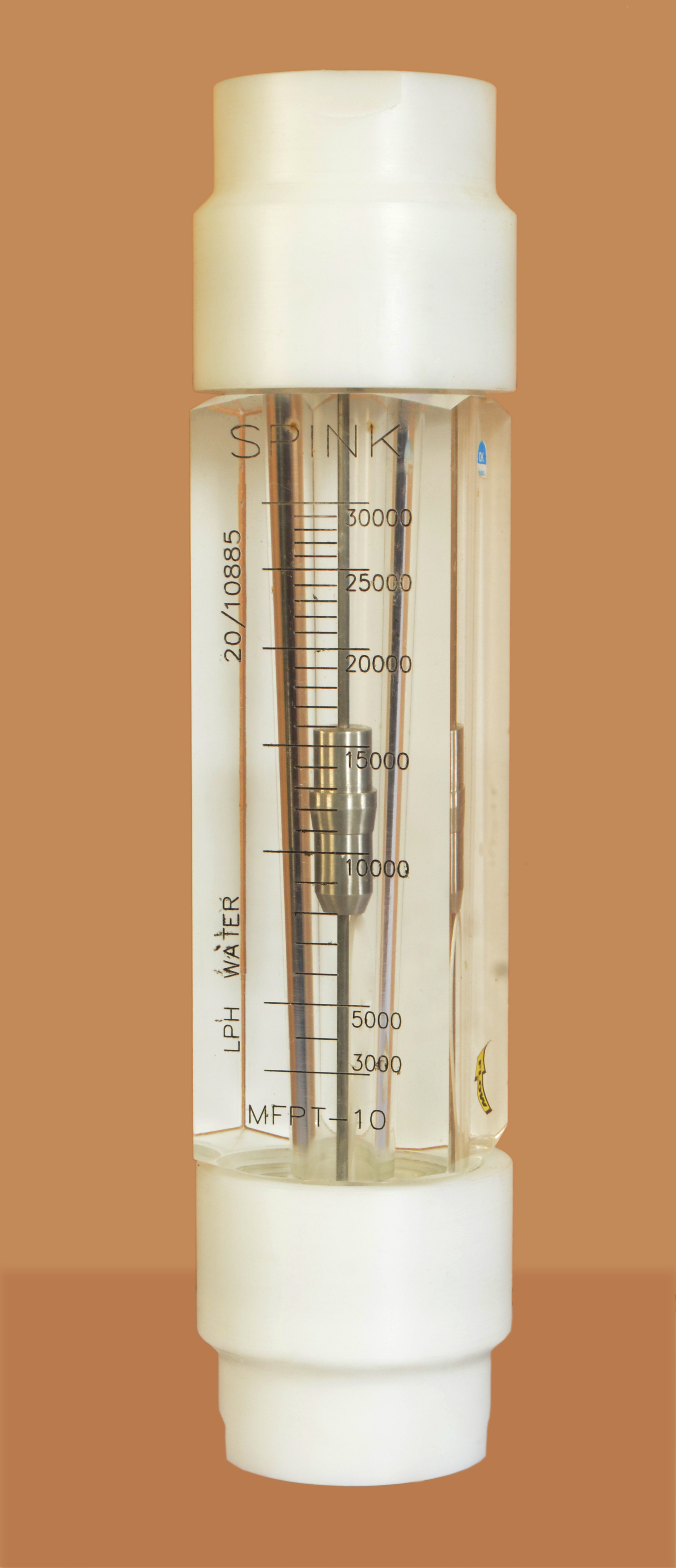

GLASS TUBE ROTAMETER

|

|

Spink Controls offer an Industrial flowmeter used to measure flowrate of liquids and gases. It operated on the Variable Area Principle, where the fluid flow raises a float in taper tube increasing the area of passage of fluid. The greater the flow, the higher the float is raised. The height of float is raised by a combination of the buoyance of the liquid and velocity head of the fluid. With gases, the buoyancy is negligible, and float responds to the velocity head alone.

.png)

|

ACRYLIC BODY ROTAMETER

|

|

Acrylic Body Rotameter is an instrument used to measure instant flow rate of Liquids and Gases and are commonly used for flow measurement. We are leading manufacturer of Acrylic Body Rotameter, supplier of Acrylic Body Rotameter in Mumbai, India.

.png)

|

PURGE ROTAMETER

|

|

The Purge Rotameter are low capacity variable area flowmeters for both liquid and gas with an excellent selection of material and scale lengths in a single product family design. They provide optimum flexibility with minimum component proliferation. The Rotameter features, a corrosion resistant, high strength stainless steel body and a safety tested operator protection shield.

.png)

|

ORIFICE PLATE AND ASSEMBLY

|

|

The Orifice Plate with Flange Assemblies are Employed for Measuring the Rate of Flow or Quantity of Moving Fluids like Liquids, Gases or Vapours The Orifice Plates are Designed as per Bs 1042-1981/ ISO 5167 & L K. Spink Standards.

Orifice Plate Types: Square Edge Concentric, Eccentric, Segmental, Quadrant Edge, Conical Entrance Plates Plate thickness: 3.18 mm, 6.35 mm, 9.52 mm, 12.7 mm as standard, other on request.

.png)

|

| CONDITIONING ORIFICE |

|

Conditioning Orifice combines a flow conditioner with an orifice plate into a highly accurate primary element.

Requires only 2 diameters of straight pipe run Upstream and Downstream from most flow disturbances Suitable for gas, liquid and steam application Available in 2 to 24 inch.

.png)

|

| |

|

| INTEGRAL ORIFICE PLATE ASSEMBLY |

|

.jpg)

|

Spink controls provides economical flow measurement products based on differential pressure principle suitable for the line size of below 2 inch. Integral orifice assembly is a specially designed prefabricated meter used when a high accuracy in flow measurement is required for extremely small flow rates. Bodies with socket-weld or threaded end connections are available.

.png)

|

| |

|

ORI FLOW METER

|

.jpg)

|

The ori-flow meter measures flow by inserting an orifice at part of the piping, generating differential pressure before and behind the orifice by means of the flow, and extracting this differential pressure by a suitable method.

Differential pressure (p1-p2) of main orifice & the flow q have shown in PDF file given below. The flow is proportional to square root of the differential pressure.

.png)

|

| |

|

AVERAGING PITOT TUBE (Annubar)

|

|

The pitot tube produces a differential pressure (dp) signal proportional to the square of the flow rate in accordance with bernoulli's theorem. This signal has two components, the high pressure (hp) and the low pressure (lp). Dp= hp-lp

When the fluid impacts the sensor, it creates a high pressure zone, greater than pipe static pressure, in front of the sensor. As the fluid moves past the sensor, it accelerates and a low pressure zone is created to the sides and rear of the sensor. Multiple sensing ports are positioned in the high and low pressure zones and an averaged differential pressure is produced. The dp increases proportionally to the square of the velocity of the fluid.

.png)

|

|

|

|

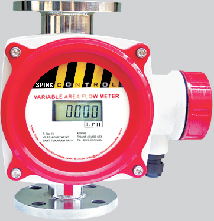

| GAS FLOWMETER |

|

The Gas Flowmeter specifically designed to measure the flow of clean gases non-corrosive to silicon. The physical pressure is measured to piezoresistive pressure sensing element where the pressure is converted into a differential voltage signal which is almost proportional to the pressure. This differential voltage is corrected and conditioned in multiple steps, and derive the flow of the gas.

.png)

|

| |

|

ELECTROMAGNETIC FLOWMETER

|

|

Spink Electromagnetic Flowmeter-Instrument designed for measuring and indicating flow and total volume of conductive liquids. As there are no moving parts in the flow profile the device can be used to measure extremely dirty liquids containing solids. The flowmeter is for use with conductive liquids only. Range of applications. The flowmete has been designed for use in all process industries including chemical, water and wastewater.

.png)

|

| SIGHT FLOW INDICATOR |

|

SPINK CONTROLS make Sight Flow Indicators which are most commonly used for monitoring liquid flow in pipelines without compromising the integrity of the piping system. Visual observation and supervision of the process flow stream are two of the main concerns. Single / double window constructions, Sight Flow Indicators are available in various figures & material. CS / SS made bodies with Toughened borosilicate Glass Windows and standard units in flanged / threaded connections provide immunity at higher temperature & pressures. These offer a quick, reliable and inexpensive way to affirm flow rate and direction, and monitor color and clarity in fluid lines.

.png)

|

| |

|

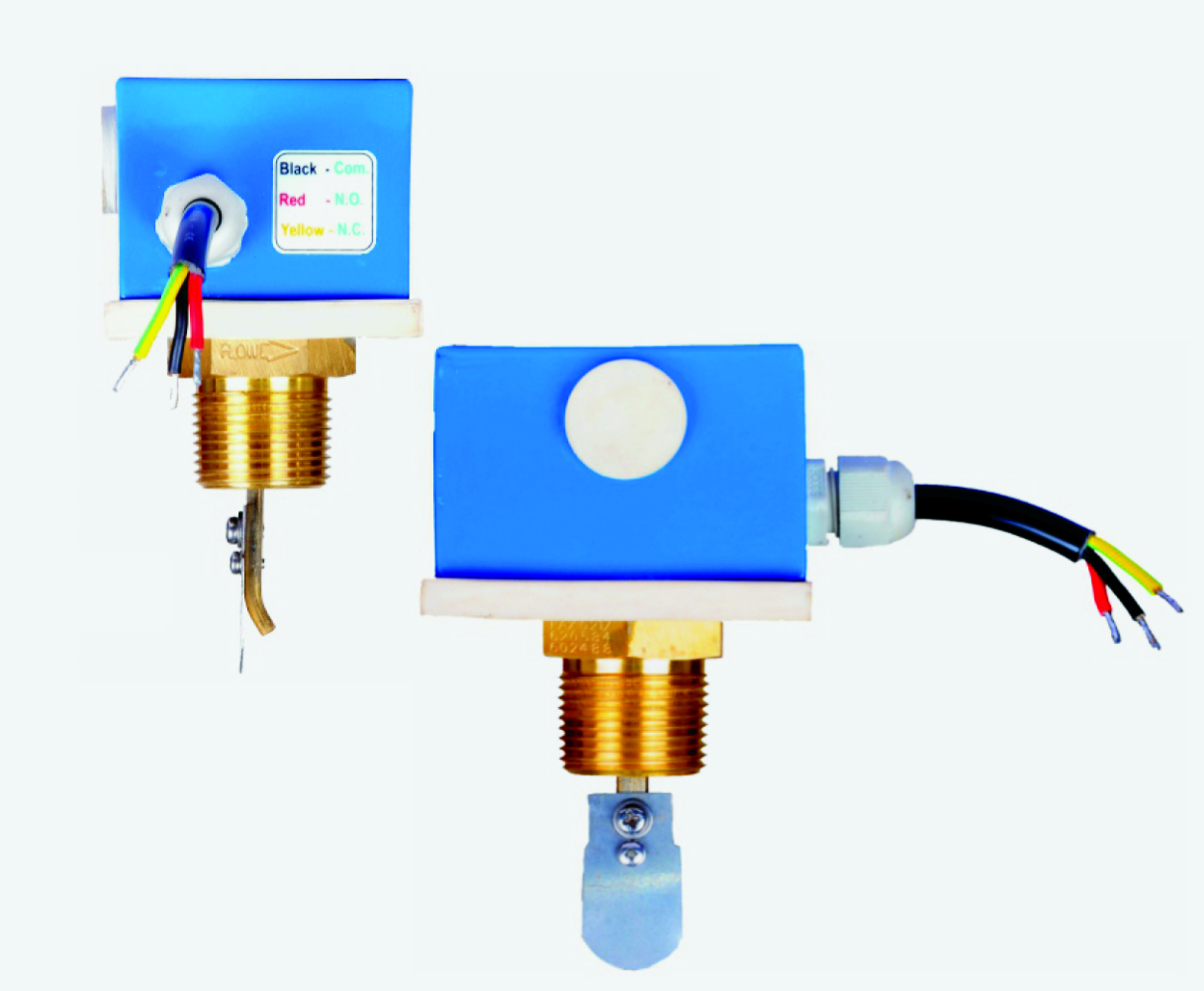

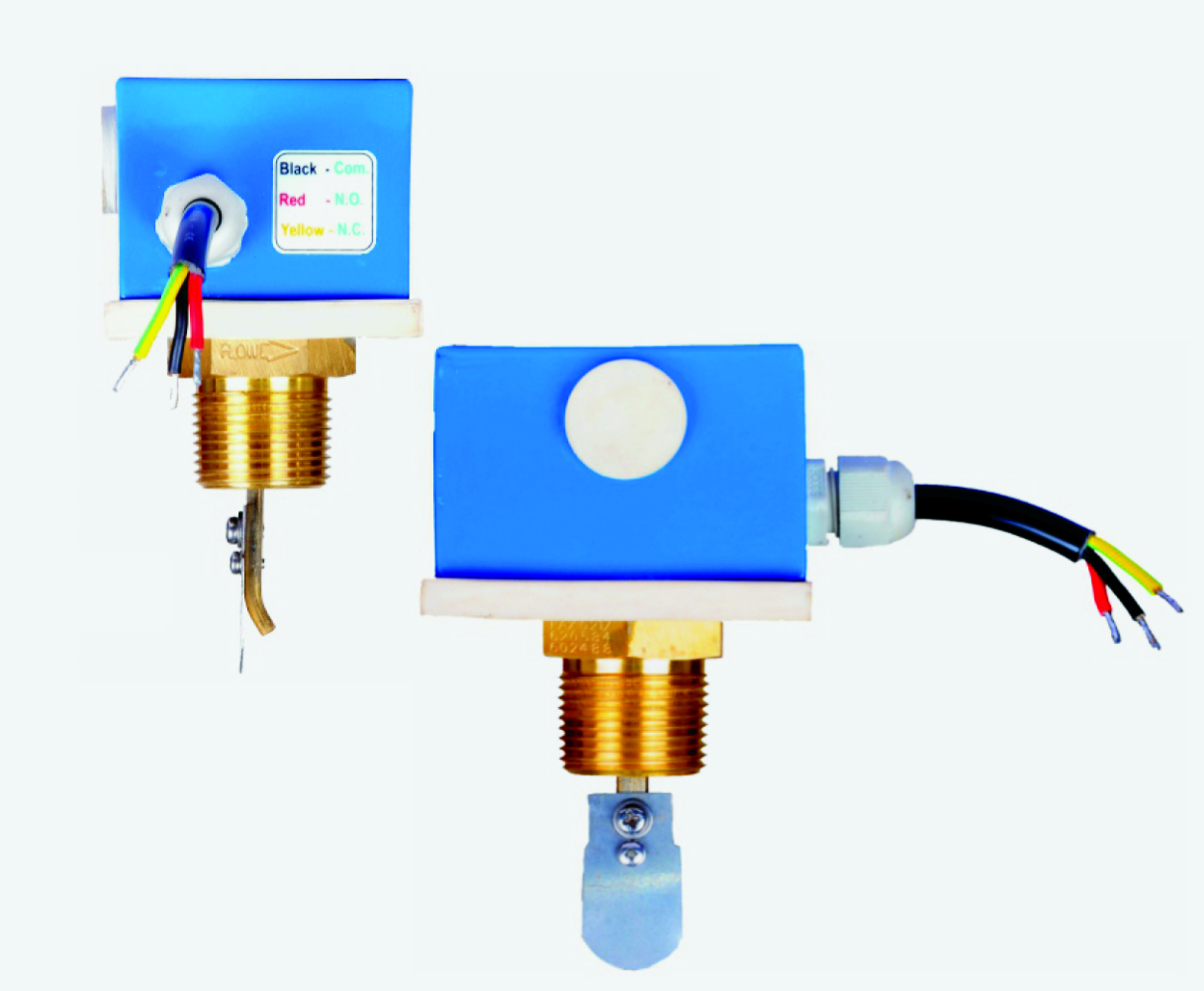

| FLOW SWITCH |

|

Compact - Durable - Accurate Easy to use flow switch. For General Industrial Applications.

.png)

|

| |

|

| FIT ( Flow Indicator Totalizer ) |

|

Flow Indicator Totalizer model instrument with multi-functionality viz. Flow Rate indication, Flow Totalizing, batch counter & alarm for instantaneous flow. It accepts mA signal proportional to flow rate from flow transmitter. Flow Transmitter can be DPT with orifice assembly, Rotameter, Magnetic Flowmeter etc. with output of 4-20 mA.

.png)

|

| |

|

| MFM ( Mass Flow Controller ) |

|

Model MFM 393 is micro-controller based arithmetical computation unit generally used in massflow applications.

4 digit LED Display. Flow Rate and Totaliser range can be configured as required even on site. Totaliser is a 8 digit LED Display. Totaliser can be reset manually from password protected PROG menu.

Power Supply for external transmitter (24VDC@100mA) is a standard feature. It eliminates need of separate power supply to power the transmitter.

.png)

|

| |

|

| DPC 965 M ( Digital Process Controller ) |

|

.jpg)

|

DPC 965 M is intended to be used for indication and control application.

7 segment RED LED display makes it visible from long distance.

4 ½ digit resolution gives accuracy as high as ± 0.3 % ± 1 LSD.

Unit accepts 4 - 20 mADC linear input, the most commonly used signal in process industry.

.png)

|

| |

|

Our Channel Partner

CLASSIC FLOW CONTROLS PVT. LTD.

Our Global Channel Partner

STATIC ENGINEERING EQUIPMENTS PVT. LTD.

| Our Solution |

Contact Deatils |

Our Services |

Downloads |

|

|

|

|

|

|

|

.jpg)

.jpg)

.jpg)